Industrial sheet metal

Professional industrial sheet metal work in Corrèze

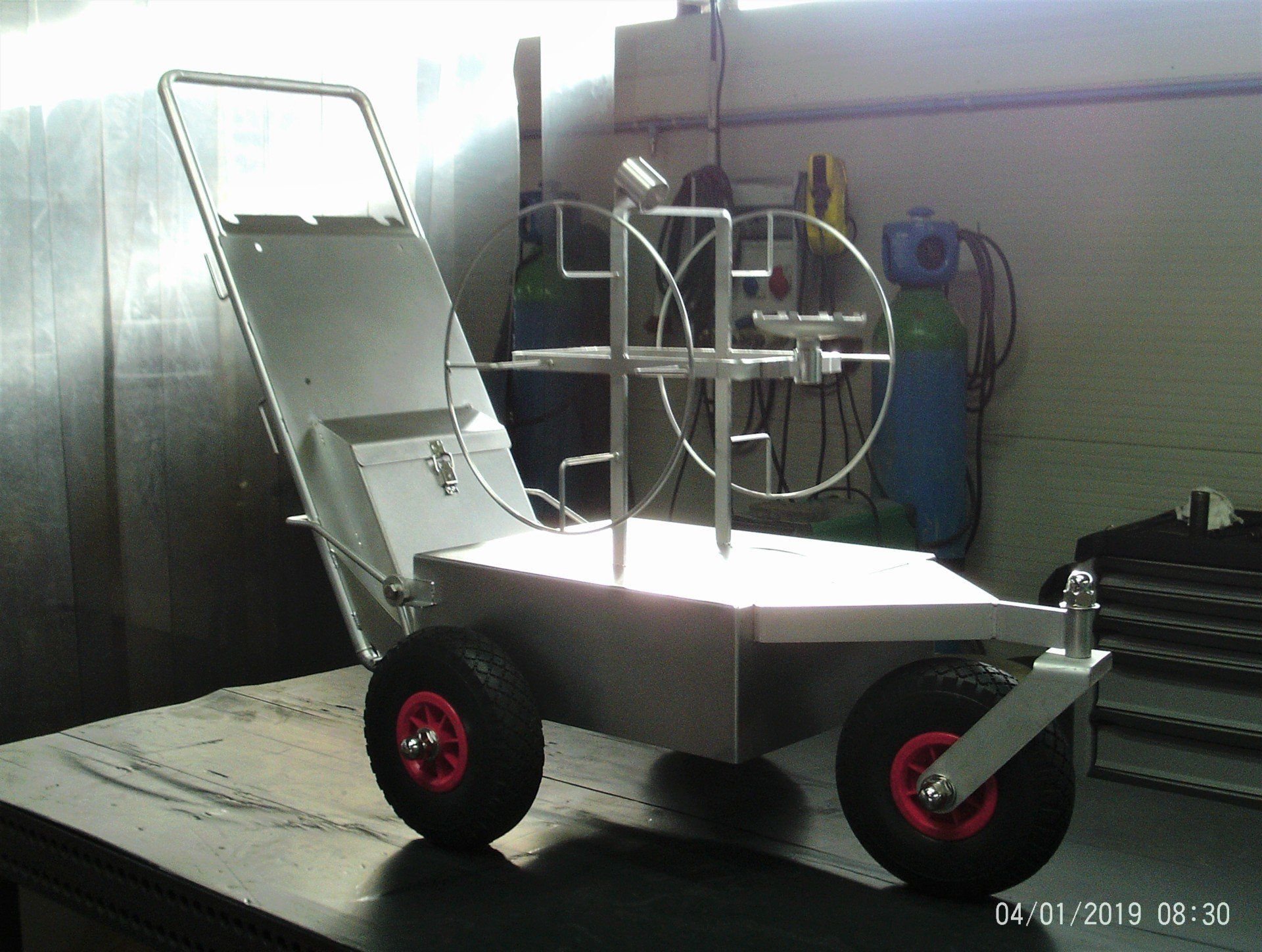

Railings, gates, storefronts, furniture, desks, trolleys, frames, hoppers, stairs etc.

French manufacturing

Serving professionals and individuals for over 10 years

Within our industrial sheet metal work, we work mainly in aluminum, steel and stainless steel. Whatever your product, let us know your ideas and your requirements. We respect your specifications to the letter in order to guarantee your satisfaction. Discover our previous achievements! Need a unique product? For all unit manufacturing, contact us! Discover our 5 sheet metal poles, essential for the production of a quality finished product. Each pole has its own area and is responsible for part of the manufacturing of the metal product.

Industrialization office pole

Let your ideas and desires speak!

The industrialization office is the very first step for industrial sheet metal work. Here we receive you and prepare a tailor-made quote for you before the product goes into design. We have advanced computer equipment for the design of your product: CAD: TopSolid, ProFirst TRUMPF programming software: TruTopsERP: GPsoft

Cutting center

When industrial sheet metal product begins to take shape

Laser

1 TRUMPF 5000W laser cutting center which can cut steel up to 25mm thick, stainless steel up to 20mm and aluminum up to 12mm with a 24-hour loading and unloading system 1 table laser cutting 4000x2000 TRUMPF 5000W laser tube We can cut flat up to 4m and on tube up to 375mm in diameter

Punching (capacity 8mm)

1 punching center TRUMPF TC 500 sheet master 3000 x 1500, 24/24 1 punching center TRUMPF 500 sheet 2500/1250, 24h / 24

Folding and welding pole

Human know-how, machine precision

Folding

We have a fleet of 6 press brakes: 2 BYSTRONIC 10 axes, 4100x250T1 BYSTRONIC 6 axes, 35Tx1.50m1 BYSTRONIC 8 axes, 4100x200T1 PERROT 8 axes, 3100x220T1 AMADA 3 axes with digital controls, Long, 1250.25T

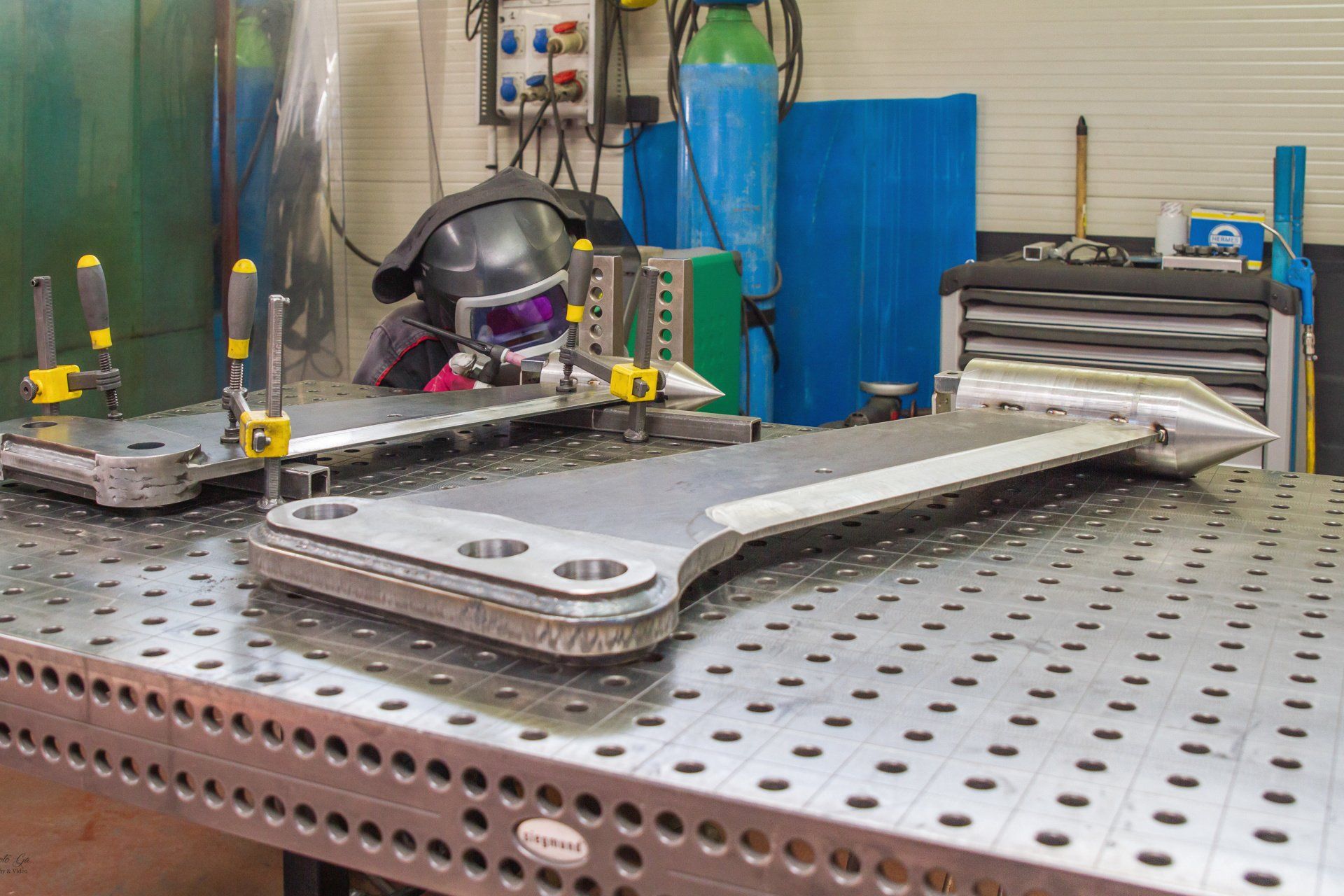

Welding

5 qualified welders are available to you in our welding department. We work with TIG, MIG welding equipment.

Finishing, preparation, packaging department

Sheet metal finishes produced by our experts to guarantee high quality

Relates to cleaning, milling, tapping and packaging activities 2 deburring barrels for deburring steel, stainless steel and aluminum 4 forklifts from 2000kg to 4000kg 2 lifting brackets Crimping machine (inserting insert, stud and baluster) Tool d and packaging